The load signs of industrial metal shelving accompany any type of shelving: pallet racks, cantilevers, mezzanines and light shelving, interlocking and picking. In fact, for each shelving there is an obligation to affix the relevant capacity signs: the sign must be placed in an always clearly visible place, directly on or near the shelving.

How are the load-bearing tables of industrial metal shelves composed?

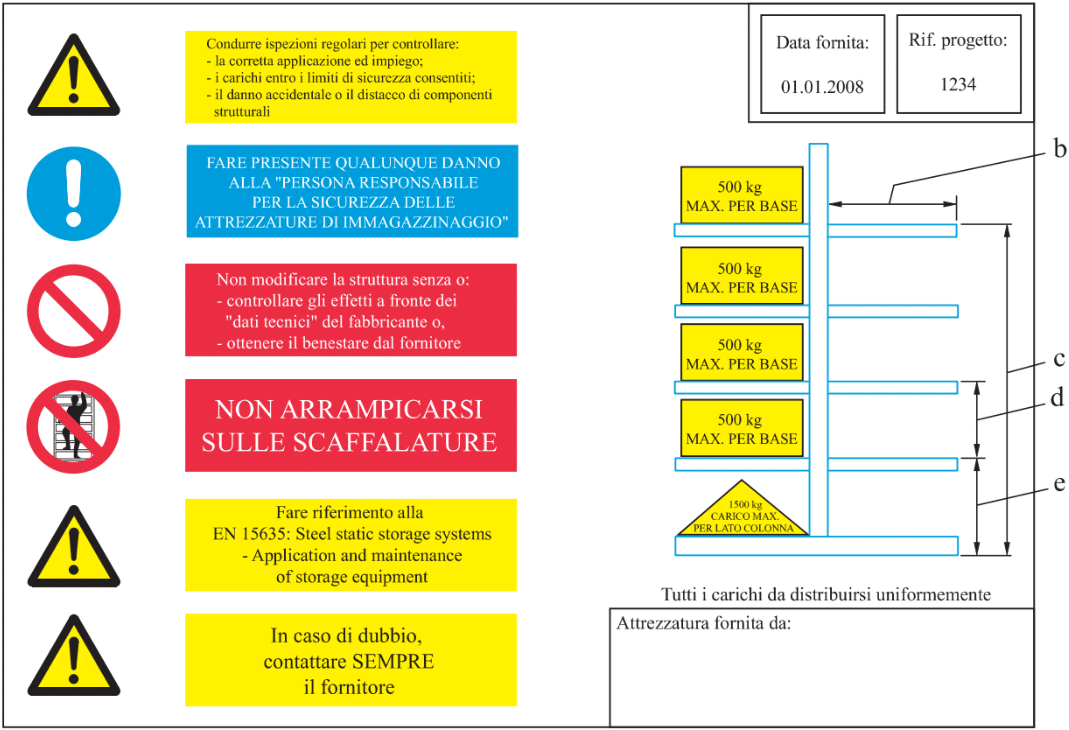

The capacity tables of industrial metal shelving use colors and symbols in compliance with the safety signage regulations, represented by directives 92/58 / EEC. The information shown in the flow chart is fundamental information for the safe use of industrial metal shelving, and since these are operational signals, for greater clarity it is necessary – we would even say fundamental – that the users of the equipment are informed and trained on how to read the flow charts.

For this reason, we at Emaf, as suppliers of industrial metal shelving, when we deliver the flow rate tables, we make a kind of “mini course” illustrating the information contained in the flow rate table and explaining how this should be read.

What must the flow rate table according to UNI EN 15635 indicate?

The flow chart – according to the UNI EN 15635 standard that defines its details – must show a series of symbols. These symbols mean “attention”, “no access”, “no access to the shelf”, “danger”, all with colors and shapes that comply with the safety signage regulations.

Beside these symbols, brief illustrative comments must be reported, therefore the indication of attention, the reference to conducting regular inspections to check the correct application of use, the attention that the loads are within the safety limits allowed, be careful of any accidental damage or detachment of structural components that can create problems for the shelving, the invitation not to climb on the shelving, not to modify the structure, to constantly check the front of the shelving, to report any damage to the person responsible for security: in fact, every person in charge of the warehouse is obliged to inform the company security manager if he sees any damage.

You are always asked to refer to the UNI EN 15635 standard and if in doubt, always contact the supplier.

The flow table then shows a drawing of the type of industrial metal shelving for which we are composing the flow table, and this generally indicates the height of the first beam, the maximum load of the entire span, the maximum load for the current level, the numbers of levels in height, always with a space that must be used to get all the information of the supplier: company name, address, telephone number and any website.

How big should the load tables be for industrial racking?

The dimensions suggested by the legislation are substantially two: as regards the pallet racks, mezzanines, drive-in shelves, the format suggested by the legislation is an A3 sheet. As for the light-filled shelving, for picking and for the cantilever racking, it is the A4 format. For cantilevers there is also the possibility of adapting the table to an A5 format for space reasons.